Shot blasting and hydroblasting are two commonly used methods of line marking removal on concrete floors. Floor preparation is key in line marking to ensure the best possible results for laying the new markings – both in terms of appearance to ensure the markings are as clear as possible and also in the longevity of the markings once they’re in-situ.

Both are relatively quick methods that can work in a range of environments, but is one better than the other? Let’s take a look at the pros and cons for both.

Shot Blasting – What is it?

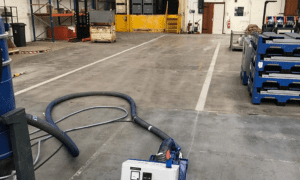

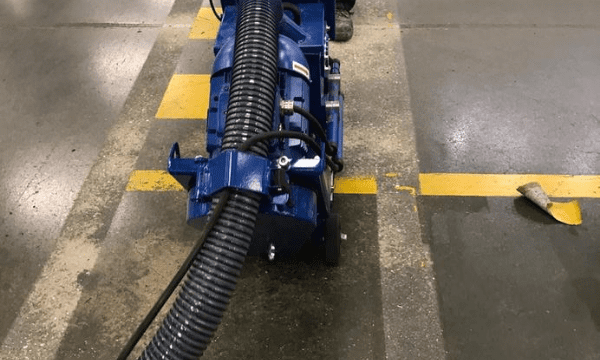

Shot blasting is a mechanical cleaning process. It uses tiny spheres of material (usually stainless steel ball bearings) propelled by compressed air, to remove debris from a surface. It is a type of abrasive blast cleaning and at Parallel Lines we use it in the preparation of surfaces prior to line marking.

Shot blasting is a 99.9% dust free process, meaning that it can even be used in food environments. Shot blasters have an integral vacuum attached that suck up the surface contaminants that are lifted during the process.

Markings can be laid on shot blasted surfaces straightaway. Unlike jobs where you might black out old markings and you need to wait for them to cure, our line marking team are ready to mark the surface as soon as the shot blaster has cleared the area.

Shot blasting is a quick process, as long as the area is cleared! We always prep the surface in advance, sweeping up any large bits of dirt and debris ready for shot blasting.

Hydroblasting – What is it?

Hydroblasting is another method for cleaning and preparing surfaces such as steel and concrete. Hydroblasting doesn’t use any abrasive medium to clean and prepare a surface. It uses only high pressure water.

Hydroblasting is more precise than shot blasting because you are working with a jet of water which can be adjusted with precision to suit the job at hand.

You might think that you need to wait for the area to dry before you can mark lines but in fact the surface is ready instantly.

The water used is collected as it clears the surface, separating the debris from the water so that it can be disposed of correctly. The water is clean and can be reused.

Find out more about the flooring preparation methods we use at Parallel Lines to ensure surface cleanliness before we undertake and line marking work. If you want to discuss any surface preparation requirements you may have then please get in touch.