In the bustling world of distribution centres, where goods flow in and out ceaselessly, safety markings are paramount for safety and efficiency.

Clear and well-defined floor markings play a vital role in ensuring that everyone working in or visiting these sites can navigate them safely.

At Parallel Lines, we specialise in internal and external industrial floor markings and surface preparation, servicing distribution centres of various sizes, including some as vast as three football pitches.

Our experience has taught us the importance of meticulous planning, especially when dealing with large-scale projects, to ensure that the warehouse environment is safe and ready for use.

Our team has successfully executed projects on live operational sites and those in the process of being set up. Leveraging our extensive experience, we are well-equipped to offer guidance on the types of line markings required and best practices for their implementation.

Key line markings typically installed to reduce the risk in distribution centres include.

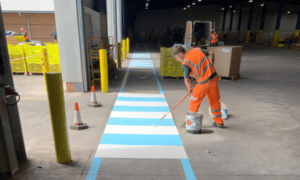

Walkways: Clear pedestrian markings ensure the safety of those visiting your centre.

Demarcation: Delineating boundaries and zones within the distribution centre.

Forklift Markings: Designated areas for forklift operations

Lorry Bays: Markings to guide and manage truck parking.

Restricted Areas: Clearly indicating areas with limited access.

Hazardous Waste Areas: Markings to identify zones for hazardous materials.

Speed Roundels: Indicators to regulate vehicle speed limits.

Hatching: Lines and patterns to regulate traffic and parking.

Loading and Unloading Bays and Pallet/Trolley Storage: Organised zones for loading and storage.

Fire Door Markings: Ensuring the legal requirements of fire safety compliance.

Zebra Crossings: Safe crossings for pedestrians.

For projects in high-traffic areas, we employ shot blasting to prepare the surface for line marking.

Shot blasting ensures that the surface is in optimal condition for effective paint adhesion.

Moreover, it creates a textured, non-slip surface, crucial for the safety of everyone on-site.

If your distribution centre is in need of health and safety line marking updates or your work environment could benefit from additional markings to enhance efficiency and safety, please don’t hesitate to contact our Parallel Lines team on info@pl-linemarking.co.uk or 01905 820 951.

We are committed to helping you create a safer and more efficient distribution centre environment, with a focus on health and safety in distribution centres and the highest standards of distribution centre line markings.