Warehouses and factories are at the centre of everything! They keep everything running smoothly yet we forget that within these hives of productivity lurks a dark underbelly, the risks and dangers of hazards. Inhaling chemicals, machinery, backbreaking tasks – these and many other hazards can cause life-changing injuries and sometimes even fatalities.

Sadly, the statistics show the reality of how many injuries are caused due to a lack of health and safety. In a report titled ‘Health and Safety at Work – Summary Statistics for Great Britain 2023’ by HSE there were some pretty shocking statistics that stood out.

- 1.8 million workers suffer from work-related ill health (new or long-standing)

- 135 workers killed in work-related accidence in 2022/2023

- 35.2 million working days lost due to work-related ill health and non-fatal workplace injury in 2022/2023

- 13,000 deaths each year are estimated to be linked to past exposure at work, primarily to chemicals or dust

These aren’t just numbers, but personal stories.

This grim reality wasn’t born overnight.

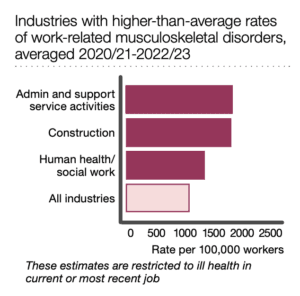

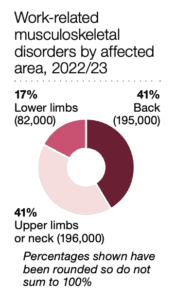

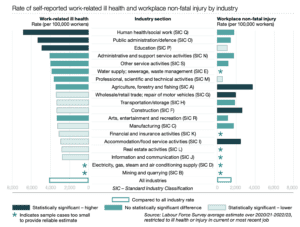

Looking at the report produced by HSE also demonstrated some further statistics in graphs. Here are some that stood out to us that we feel are important to share.

A hard hat wasn’t always a standard accessory, and working conditions constantly presented a plethora of hazards. The tide began to change in the 19th century, with health and safety evolving from a distant thought to the forefront of all worker’s minds.

So how did we get to where we are today?

1833 was the year that marked the dawn of official safety concerns. Factory inspectors were appointed, tasked with safeguarding workers in a booming industrial landscape. This was the first significant step towards reducing workplace injuries, especially in harsh conditions and long days.

1842. This was the year we saw the spotlight shift to the subterranean world. Mines, notoriously dangerous, received much-needed attention with the formation of the mines inspectorate. This improved working conditions and offered miners a better chance at returning home to their families.

In 1895 quarries joined the safety movement, with their dedicated inspectorate. This mirrored the efforts made in the mines, tackling dangers inherent to the extraction industry.

1956. This was the year for agriculture, long overlooked, they finally came under the safety umbrella. The Safety, Health and Welfare Provisions Act of 1956 brought much-needed regulations to farms, aiming to curb accidents and the spread of diseases.

1959 was the atomic age that dawned with a curious eye on safety. The Nuclear Installations Act 1965 established strict standards and limitations for handling formidable weapons, recognising the immense risks involved.

1957 was the year we saw the Health and Safety at Work Act arrive. This comprehensive legislation offered broad protection for workers across various industries, from retail to factories. It provided a vital framework for ensuring that people went home safely. The establishment of the Health and Safety Commission further solidified this commitment.

And from there the journey has continued with acts like the Safety Representatives and Safety Committees Regulations (1977), the Control of Lead at Work Regulations (1980), and the Notification of Accidents & Dangerous Occurrences Regulations (1980). Each step refined and strengthened the safety net, ensuring ever-higher standards for every worker’s well-being and safety.

Real-life cases

Although there are many legislations in place to make working environments a safe place, there are still accidents that occur. We conducted some research to find some disasters that occurred over the last 10 years in the UK.

A farming business has been fined after a walker died in a cattle incident

A farming business has been fined after a member of the public died after being butted several times by a cow in front of two of the victim’s grandchildren.

The farm business failed to properly manage cattle movement on a public bridleway. Lacking basic safety measures such as signs and lookouts to warn oncoming walkers. This tragedy highlights the importance of responsible farm practices and ensuring public safety in shared spaces.

The farm was fined £72,500.

Company fined £900,000 after a man was crushed to death

A company in Leicestershire has been fined £900,000 after a father-of-two was crushed to death.

The father-of-two tragically lost his life after being crushed by a scissor lift at Nationwide Platform Limited’s workshop. The company was fined for failing to prioritise safety, neglecting both risk assessment of operating machinery with moveable controls and adequate supervision.

This fatal incident, unfortunately, one of 29 similar tragedies in 2022/23, serves as a reminder of the dangers present in workplaces and the critical role proper safety measures play in preventing such fatalities.

A yard manager and company were sentenced following the death of an employee in a shredder

A yard manager has been jailed for seven-and-a-half years and the company fined £400,000 after an employee was killed in an industrial shredder.

In a horrific act of negligence, a yard manager was sentenced to seven-and-a-half years in prison, and his company was fined £400,000 following the death of an employee. The manager recklessly placed his employee atop a jammed industrial shredder, exposing him to unthinkable danger.

CCTV footage captured the harrowing scene, solidifying the manager’s gross violation of safety violation. This preventable tragedy highlights the chilling consequences of neglecting safety protocols and reinforces the vital role responsible leadership plays in protecting lives.

A Welsh council has been fined £2M after man killed carrying out road repairs

A road worker tragically lost his life while repairing a highway due to the Council’s unsafe work practices. Inadequate safety measures, like a proper buffer zone, exposed workers to traffic, leading to the victim being struck by a vehicle.

This preventable tragedy cost the council a hefty £2 million fine and serves as a reminder of the importance of prioritising worker safety.

The victim widow’s plea for improved safety highlights the human costs of negligence and urges all to ensure such tragedies never occur again.

Implementing Safe Practices

Today’s warehouses, factories and industrial sites, while modernised, face evolving threats. Automation introduces risks of entanglement and crushing, while material handling poses constant musculoskeletal stresses.

Chemical exposure, noise pollution, and even seemingly mundane tasks like repetitive lifting contribute to a silent epidemic of occupational illnesses. These are not inevitable costs of progress – they are avoidable consequences of negligence.

Every industrial warehouse and factory must prioritise risk assessments, not as tedious paperwork, but as life-saving exercises. Comprehensive safety training, covering everything from proper lifting techniques to hazard identification, making sure employees become active participants in their well-being.

Modern machinery demands rigorous maintenance, not neglectful shortcuts. Enforcing safe work practices, from designated traffic lanes for forklifts to mandatory PPE usage, must be a priority in all workplaces where necessary.

One safety precaution many people forget is clear and effective safety signage and markings. They are the silent health and safety officer, guiding workers and warning them of invisible dangers, and that their safety is valued.

Line markings are also another crucial aspect of health and safety. These markings define pathways, separate vehicles from pedestrians, and highlight danger zones. They ensure smooth traffic flow, preventing collisions and fostering a predictable environment where hazards are readily visible.

Ultimately these markings are a silent conversation on safety, constantly reminding workers of the risks of accidents and preventing these risks from occurring. Every warehouse, distribution centre or industrial setting should have clear line markings.

If you require health and safety line markings at your distribution centre, warehouse or industrial setting feel free to get in touch and we can support you in getting your health and safety up to scratch. Contact our team at info@pl-linemarking.co.uk or 01905 820 951.

Prioritising health and safety in warehouses and factories is not just a legal obligation, but a dedication to your employee’s safety and well-being.

Remember, shortcuts in safety come at a heavy price – a price measured in shattered lives and lost potential.